Wisewool™ Glossary

The Wisewool™ glossary decodes wool terms in plain English so manufacturers, makers, buyers and curious minds can choose, care for and confidently use wool. This list of terms is organised alphabetically.

Wisewool™, wool bales on a truck

Bale Opener

A bale opener is a handheld steel tool used to hinge open wool bale clips. Typically shaped like a blunt hook, it allows operators to safely open compacted wool bales.

Batting

Wool batting is where sheets of carded wool are needle-punched in layers for use in upholstery, bedding, and mattresses, where loft, breathability, and comfort are valued. Wisewool™, WiseLayer™ is an example of batting.

Wisewool™, WiseLayer™ 500gsm High Loft Batting

Carding

Mechanical alignment of fibres using toothed rollers to produce a uniform web or sliver for downstream processes such as spinning or nonwovens. In batting, the wool is first carded and then layered before being needle-punched. In knops, the wool is carded in the reverse direction.

A wool carding machine making WiseFill™ wool knops.

Clean yield

Percentage of usable fibre after removing grease, dirt, and vegetable matter through the scouring process.

Colour

A measure of brightness and yellowness that affects dyeing. In New Zealand, colour measurement on greasy auction lots is widely used to inform trading.

Wool colour is measured using two values: Y for brightness and Z for yellowness.

A high Y value means the wool is bright and clean, while a low Z value means it has little to no yellow tint. These measurements are taken with a special light-reflecting machine to help assess the wool’s quality and suitability for different uses.

Crimp

The natural, regular waviness along a wool fibre. It gives the fleece elasticity, bulk and resilience

Crimp in Wool Fibres

Crutching

The removal of wool from around the tail, hindquarters, and sometimes the belly of a sheep to maintain hygiene, reduce flystrike risk, and make shearing easier. Often done before lambing or during warm months.

Dags

Lumps of soiled, matted wool around the hindquarters that are crutched or trimmed for hygiene and to help prevent flystrike.

Dipping

Applying a liquid or spray to control external parasites such as lice.

Docking

Removing a lamb’s tail for hygiene and flystrike prevention, performed under animal welfare guidance and undertaken to ensure the animal’s long-term health

Dosing

Administering liquid drench to control internal parasites and maintain flock condition. NZFAP have strict withholding periods in place.

Nicky next to a Fadge of future Wisewool™.

Fences

Wire and wooden battened barriers that contain mobs of sheep in one area, so rotational grazing can be done to provide the best nutritional value to the sheep.

Fibre

An individual strand of wool that, together with others, forms the staple and ultimately the yarn or web.

Fleece

Sheep fleece is the full coat of wool shorn from a sheep in a single piece. It’s a natural bundle of protein fibres (wool) that grows from the sheep’s skin and, when freshly shorn, contains natural oils (lanolin), dirt, vegetable matter and is commonly called greasy fleece.

Grab Sample

A representative hand sample is often taken for visual inspection, alongside core tests for parameters like length after carding.

Greasy Wool

Wool, as it is shorn from the sheep, is unwashed and still contains lanolin and natural impurities. Many auction lots in New Zealand are offered in this form.

GSM

Grams Per Square Metre is the measurement of the weight and density of the wool batting, indicating its thickness and quality.

HD Bales

High-density bales produced by modern wool presses to optimise storage and freight of scoured wool - normally pressed to weigh around 400kgs.

HL

High Loft, Low Density, describes a thick, airy batting with high volume but light weight.

1000GSM HL Wisewool™ WiseLayer Batting

Hogget wool

Wool shorn from sheep around 12–18 months old; longer and stronger than lambs wool.

IWTO

The International Wool Textile Organisation is a global body that establishes testing standards, specifications, and trading rules for wool, ensuring consistency, transparency, and fairness in the international market.

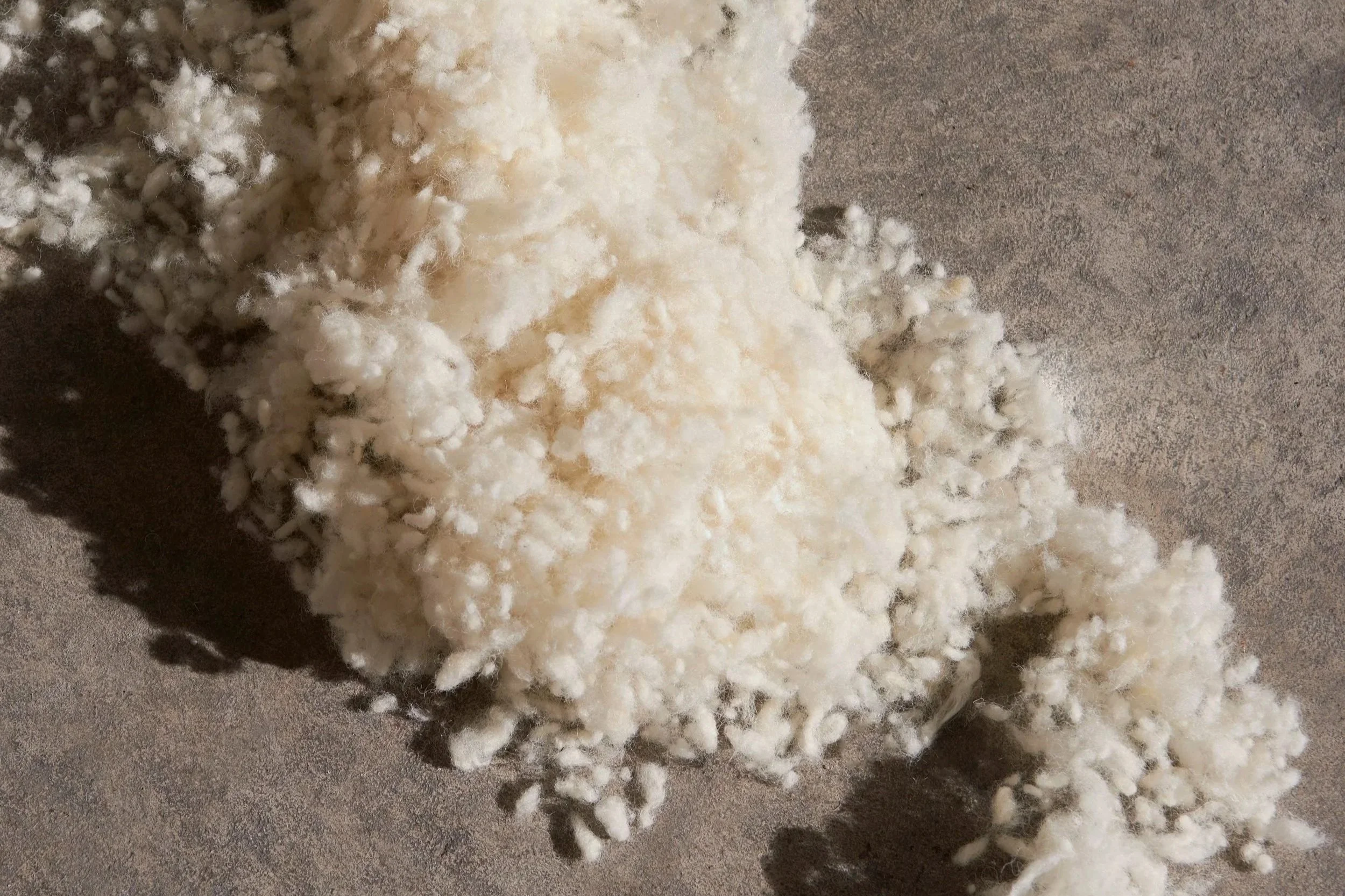

Knops

A wool knop is a small, tightly entangled, springy ball of wool fibre, often used as a natural filling in cushions, pillows, upholstery, and soft toys.

100% Pure Wool Knops

Lines

Groups of wool bales of similar quality, prepared for sale.

LL

LL or Low Loft, High Density, describes a thinner, compact material with a firm, tightly packed structure.

1000 GSM Low Loft Wisewool™, WiseLayer™ Batting

Lot (or Line, Sale Lot)

A catalogued group of similar bales prepared and sold together at auction or by private treaty. The lot system helps match consistent wool to specific mill requirements and is essential for traceability.

Micron

A micrometre, one millionth of a metre. In wool, it expresses average fibre diameter and strongly influences end use and handle. Lower microns are finer, higher microns are stronger.

A mid-point break in wool which indicates a weakness in the fibre.

Needle Punching

A nonwoven method where barbed needles repeatedly pass through the web of fine layers of wool to entangle fibres into a strong, coherent blanket without weaving or knitting.

New Zealand Farm Assurance Programme (NZFAP)

The national assurance programme that verifies on-farm practices for origin, animal welfare, food safety, and traceability across New Zealand’s red meat and wool sectors. Certification signals independently checked good practice.

Paddock

A fenced section of pasture where sheep graze and are rotated for pasture health.

A sheep in a New Zealand Paddock

Pasture

A piece of land covered with grass or other plants where animals, such as sheep, cows, or horses, can graze and feed.

New Zealand Sheep Pasture

Presser

The Presser is the person operating the wool press, responsible for bale integrity, weights, and tally records.

Romney wool

The dominant strong wool breed in NZ; produces bulk, durable wool. Perendale and Coopworth are other common strong wool breeds in NZ

SATRA

An independent research and testing organisation that, among other services, assesses textile performance, durability, and safety. In the wool sector, it provides quality verification for end-use applications such as upholstery and bedding.

Scouring

Industrial washing that removes grease, dirt, and vegetable matter from greasy wool to produce clean fibre ready for processing.

Second Shear

A shorter, finer regrowth is taken when sheep are shorn twice a year. This provides higher-quality wool and promotes better animal health.

Shearers

Professionals trained to remove the fleece of wool from a sheep.

A shearer shearing a sheep.

Skirtings

Wool pieces are removed from the edges of the fleece; generally, these are lower in quality.

Different wool staple lengths.

Staple Strength

The force required to break a staple, reported in newtons per kilotex. Higher strength staples better withstand processing and reduce breakage. A higher staple strength indicates a higher quality.

Suint

The dried sweat salts are found in greasy wool.

Topmaking

Process of combing wool into long, parallel fibres for spinning

Wadding

Wadding is another name for batting. WiseLayer™ is called batting or wadding in some countries.

WiseFill™

A 100% pure New Zealand wool loose-fill product from Wisewool™. Small, soft wool knops (tiny round clusters of wool) are engineered and designed as a natural alternative to synthetic fills.

WiseFill™ 100% Pure Wool Knops from Wisewool™

WiseLayer™ 350HL Batting from Wisewool™

Wool clip

The total amount of wool shorn from a flock in a season.

Wool store

A facility where wool is received, tested, classed, and prepared for sale or export.

The Wisewool™ team in a wool store.

Worsted

A spinning process that produces smooth, strong yarn from longer fibres.

A wool press used in a woolshed.

Woolshed

The building where sheep are shorn and the wool is first classed.

Yield

The proportion of clean fibre remaining after grease, dirt, and vegetable matter are removed, reported on recognised bases under IWTO methods.

As the global experts in strong wool we can answer any question you have about strong wool. Contact us to find out how we can help you.